Delco Manufacturing

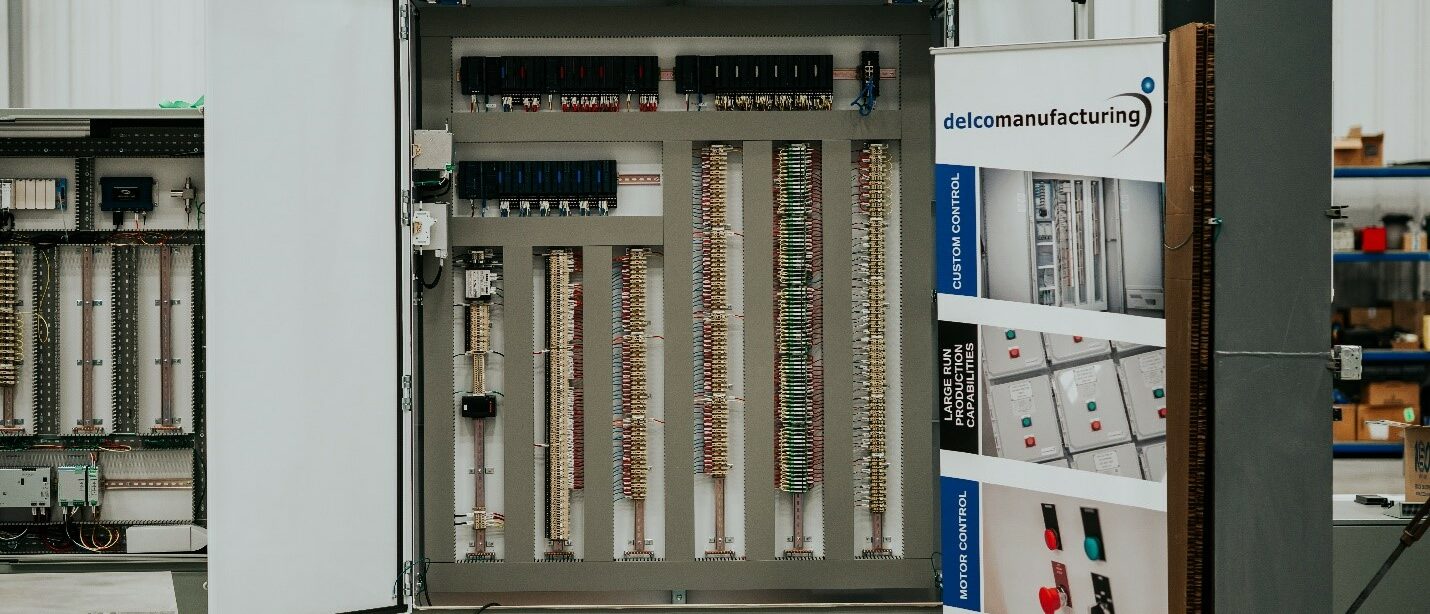

Delco Automation offers extremely skilled technicians to furnish CSA electrical control panels for your next project. We provide the best practices in the industry to deliver your electrical control panels directly to your site; they are pretested and shipped to ensure reliable operation upon arrival.

We can manufacture the majority of your custom CSA electrical control panels- from DCS, PLC, RTU, and Operator Consoles to Custom Motor Control and Power Products.

We have delivered 1000’s of electrical and control projects to a diverse range of industries. Major industries include: water/wastewater, mining, security, manufacturing, oil & gas, petrochemical, food & beverage, forestry, pulp & paper, agriculture.